MS Angles: The Versatile Edge In Eco-Friendly Construction

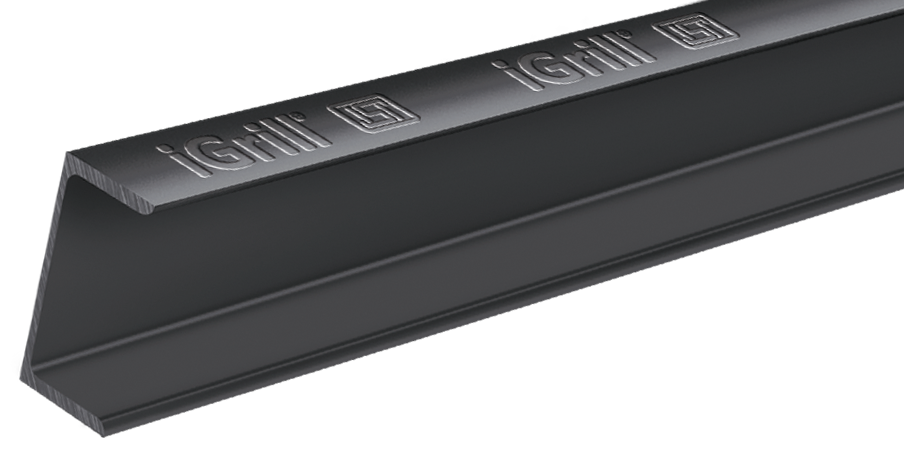

Today, the field of sustainable construction is constantly developing, and architects and builders are looking for new construction materials that are worthy of consideration in terms of functionality and environmental friendliness. The new kid on the block in this chase is MS angles, or mild steel angles, to be precise. What are MS Angles? MS angles are structural profiles, L-sections made from mild steel through the technique of hot rolling. Due to their basic but strong structural frame, they offer a number of benefits when used in construction projects. Why are MS Angles Eco-Friendly? Here’s how MS angles contribute to sustainable building practices:- Durability & Longevity: MS angles offer first-rate features in terms of strength and resistance to corrosion. This is the case with structures that may undergo little changes in replacement and repair, resulting in minimum waste generation within their life cycles. High Recyclability: Steel is, on average, one of the most recycled materials in the world, and it is the major component in MS angles. These angles can be easily recycled and reused at the end of their lifetime, thereby minimizing the anthracite’s requirements for virgin material. Material Efficiency: According to the angles of MS, adequate utilization of material is possible. Both of these shapes are rather accurate L-shapes, and it was identified that they have lower material leftover issues than other structural parts during the fabricating and constructing processes. Reduced Construction Time: MS angles are manageable on site since they are easy to fit; therefore, on-site construction time is significantly reduced. This holds implications of utilizing less energy in construction and the relative speed at which construction projects are accomplished. Beyond Sustainability: Advantages of MS Angles in Construction MS angles go beyond their eco-friendly credentials to provide a multitude of benefits for builders:- Versatility: Their L-shaped geometry makes them suitable for use in framing walls, roofs, building supports for beams and floors and many others. Customization: MS angles come in different sizes and thicknesses, and they can, therefore, be cut to the required size and thickness. Cost-Effectiveness: MS angles are cheaper than other structural materials, such as wood or concrete, in construction. Fire Resistance: Fire resistance features are intrinsic to steel; therefore, using MS angles is perfect for enhancing the fire safety of buildings. HMB Group: Your Partner in Sustainable Construction At HMB Group, we are always aware of the need to involve environmentalism in the construction business. We stock quality MS angles along with other green building products and solutions to assist you in completing your green building initiative. Conclusion The present study’s MS angles reflect a promising option for architects and builders who would like to implement supremely efficient and eco-friendly structures. Their coverage of sustainability factors, flexibility, and comparatively cheaper construction materials make them an asset in the current construction equipment tool. Find the best MS Steel manufacturer in India.